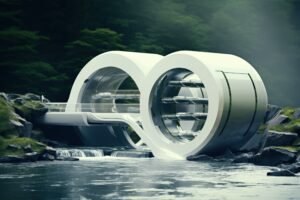

In the motors and generators industry, high-performance pumps play a pivotal role in ensuring optimal efficiency and reliability in power generation. These pumps are designed to handle the demanding conditions of power plants, where precision, durability, and consistency are crucial for uninterrupted energy production.

Importance of High-Performance Pumps in Power Generation

Power generation facilities rely on high-performance pumps to move liquids, gases, and coolants efficiently throughout the system. These pumps are essential for processes such as cooling, water treatment, and lubrication in generators and turbines. The efficiency of the pumps directly impacts the overall performance of power generation units, minimizing energy losses and reducing operational costs.

High-performance pumps are engineered with advanced materials and cutting-edge technology to withstand the high-pressure environments found in power plants. These pumps deliver exceptional flow rates, robust durability, and high operational reliability, ensuring power generation processes run smoothly and with minimal downtime.

Key Features of High-Performance Pumps

-

Enhanced Durability: Built to endure high temperatures and extreme pressure conditions, high-performance pumps ensure longevity, reducing the need for frequent maintenance or replacement.

-

Energy Efficiency: These pumps are designed to operate with minimal energy consumption, optimizing power output and lowering operational costs in power generation plants.

-

Corrosion Resistance: Given the aggressive environments in power plants, high-performance pumps are constructed from corrosion-resistant materials that ensure longevity and reduce maintenance intervals.

-

Advanced Technology: Incorporating state-of-the-art design and materials, high-performance pumps provide superior hydraulic performance, ensuring efficient fluid management across various systems.

Applications in Power Generation

High-performance pumps are crucial in several areas of power generation:

-

Cooling Systems: Pumps circulate water or coolant to regulate the temperature of turbines and generators, preventing overheating.

-

Water Treatment: Pumps ensure the flow of water through filtration systems to maintain water quality and prevent contamination.

-

Lubrication: Pumps supply lubrication to essential mechanical components, reducing wear and tear and maintaining system efficiency.

High-performance pumps are indispensable in the power generation sector, providing the reliability and efficiency needed to optimize plant operations. With advancements in pump technology, these solutions continue to evolve, offering even greater energy savings and operational efficiencies. The incorporation of such pumps in power plants is a key strategy for ensuring consistent energy production and maintaining the integrity of critical infrastructure.