The global shift towards energy efficiency in industrial applications has led to the emergence of innovative materials that enhance motor performance. Additive metals—such as high-purity copper alloys, lightweight aluminum composites, and advanced magnetic materials—are revolutionizing the way industrial motors operate. These materials not only improve efficiency but also reduce heat losses, extend motor lifespan, and contribute to sustainability in industrial sectors.

The Role of Additive Metals in Industrial Motors

Industrial motors are integral to manufacturing, oil and gas, and water treatment sectors, where efficiency gains can translate into significant cost savings and reduced carbon footprints. The introduction of high-performance additive metals has enabled manufacturers to produce motors with:

- Lower electrical resistivity – resulting in reduced energy losses.

- Improved thermal conductivity – enhancing heat dissipation and preventing motor overheating.

- Stronger magnetic properties – boosting torque and overall efficiency.

Key Additive Metals Transforming Industrial Motor Design

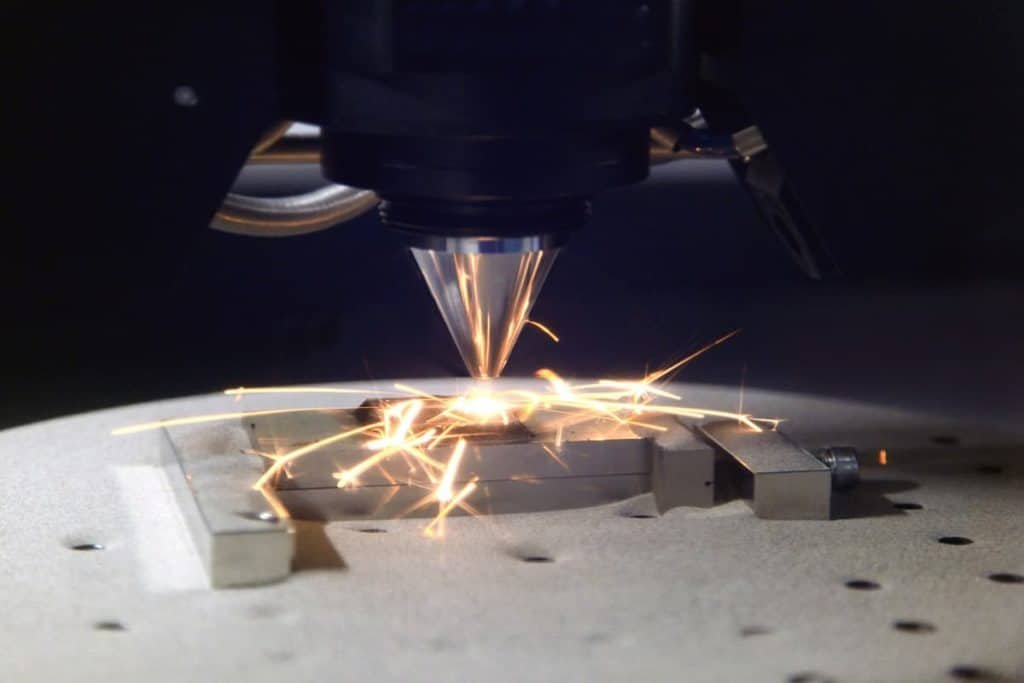

- Copper-Alloy Windings:

- Copper alloys with silver or beryllium reduce electrical resistance, improving efficiency in high-power motors.

- These materials also offer enhanced corrosion resistance, making them ideal for harsh industrial environments such as offshore oil rigs and chemical plants.

- Silicon Steel for Core Efficiency:

- The addition of silicon to steel laminations minimizes energy losses due to eddy currents.

- This technology is widely used in high-efficiency induction motors in the GCC region, where energy conservation is a priority.

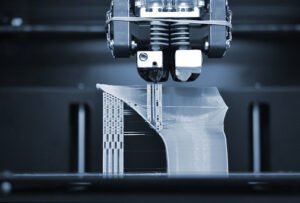

- Lightweight Aluminum Composites:

- Advanced aluminum alloys reduce motor weight without compromising strength, making them perfect for applications in electric vehicles (EVs) and renewable energy systems.

- Cobalt and Rare-Earth Magnets:

- Permanent magnet motors utilizing neodymium and cobalt alloys offer superior torque density and reliability.

- These are essential for servo motors, robotics, and high-performance pumps.

Sustainability and Energy Standards Compliance in the GCC

Countries across the GCC are implementing stringent energy efficiency regulations, encouraging industries to transition toward IE3 and IE4 high-efficiency motors. The use of additive metals aligns with Saudi Vision 2030, UAE’s green energy initiatives, and Qatar’s sustainability goals, ensuring compliance with international energy standards.

The integration of high-performance additive metals is reshaping industrial motor efficiency, driving sustainability, and reducing operational costs. As industries prepare for the future, the adoption of these advanced materials will be critical for meeting global energy standards.